-

Property & Casualty

Property & Casualty Overview

Property & Casualty

We offer a full range of reinsurance products and the expertise of our talented reinsurance team.

Expertise

Publication

Recycling of Large Lithium-Ion Batteries From a Property Insurance Perspective

Publication

The Future of Cryptography and the Rise of Quantum Computing

Publication

Personal Injury Compensation in Europe: An Updated Comparison Among Different Systems Within the European Market

Publication

Looks Like Inflation Is Sticking Around. What Do We Do Now? [Part 3 of 3]

Publication

Motor Insurance in the Post-Pandemic Era -

Life & Health

Life & Health Overview

Life & Health

Gen Re’s valuable insights and risk transfer solutions help clients improve their business results. With tailor-made reinsurance programs, clients can achieve their life & health risk management objectives.

UnderwritingTraining & Education

Publication

The Future Impacts on Mortality [Video]

Publication

Thinking Differently About Genetics and Insurance Business School

Business School

Publication

Fraud Survey in the UK & Ireland Sheds Light on Insurer Best Practices

Publication

Fight Against Fraudulent Claims – Highlights From Our South African Survey Moving The Dial On Mental Health

Moving The Dial On Mental Health -

Knowledge Center

Knowledge Center Overview

Knowledge Center

Our global experts share their insights on insurance industry topics.

Trending Topics -

About Us

About Us OverviewCorporate Information

Meet Gen Re

Gen Re delivers reinsurance solutions to the Life & Health and Property & Casualty insurance industries.

- Careers Careers

Large-Battery Storage Facilities – Understanding and Underwriting the Risks

October 28, 2021

Leo Ronken

English

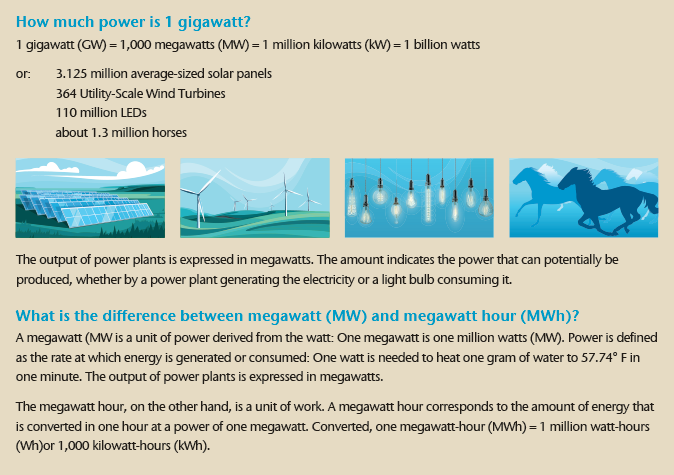

Deutsch

As efforts to decarbonize the global economy gather pace, new large-battery storage facilities are being built around the world at lightning speed. Intended to support the expansion of renewable energies and compensate for power fluctuations in energy grids, the U.S. Department of Energy has recorded more than 1,600 storage facility projects worldwide, including nearly 600 lithium battery facilities.1 In Australia, approximately 56 facilities have been constructed or are in planning stages, each with a capacity of more than 10 MW and a storage capacity of more than 10 MWh.2

However, with the technology involved still in its relative infancy, little information is available on which to base risk assessments from an insurance perspective. This article aims to provide a useful overview of losses to date, important fire protection measures, and underwriting guidelines for Property underwriters tasked with evaluating the exposure of these facilities.

What are large battery storage systems?

Strictly speaking, the correct term for these facilities is “large-scale accumulator storage systems”. They consist of one or more modules in which accumulators are combined into groups. The individual batteries usually fill floor-to-ceiling racks and the overall storage capacity is usually only limited by the space available to accommodate the storage modules.

Such systems have storage capacities upwards of approximately 50 kWh. They are constructed as standalone objects, either indoors or outdoors and contain all the components necessary for their operation (e.g. battery systems, power electronics, energy management, extinguishing system, air conditioning, containers, etc.). Relatively simple and inexpensive to build, maintain and operate, a large increase in the number of plants is expected in the coming years.3

These storage systems also represent a simple and inexpensive option for stabilizing the power grid, storing electricity, and managing peaks and troughs in power generation from renewable energy sources.4 For example, surplus wind energy – when optimal conditions for power generation do not coincide with peak demand – can be stored and released to the grid as required. With rising energy demand, weather-dependent feed‑in energy producers, and a growing number of other fluctuating energy producers, the storage systems can help ensure the necessary security and quality of energy supply on a permanent basis.

Most large battery storage facilities currently use lithium‑ion accumulators. According to a study by Navigant Research, more than 28 GW of lithium batteries will be used for stationary storage applications by 2028.5

However, other battery systems are also being developed; for example, the construction of battery systems with sodium‑ion6 as well as iron‑air cells.7 Since the accumulator/battery market is currently in a developmental phase, further large-scale battery systems employing different technologies are to be expected.

Loss events

Fires involving lithium‑ion batteries (which are mostly based on lithium-iron-phosphate or lithium-nickel-manganese-cobalt) are very difficult to extinguish due to the encapsulation and the substances they contain and the noxious smoke and fumes they generate. Given their ubiquity, and the specific problems they present, they are the key focus of this article. Fires in large-scale battery storage facilities are not uncommon and include the following:

- Between 2017 and 2019 South Korea witnessed 23 major fires, with total damages upwards of USD 32 million.8

- Europe has already witnessed two major fires, in Belgium in 2017,9 and in Liverpool, England in 2020.10

- In the U.S., a serious fire in 2019 claimed the lives of two firefighters at a 20 MW facility consisting of three modular battery containers and a switchgear container that has been in operation since 2018.11

- In Beijing in April 2021 a fire broke out in a 25 MWh energy storage facility using lithium iron phosphate batteries.12 The cause is suspected to be wear and tear.

- In August 2021 a lithium‑ion battery module caught fire during a test at one of the world’s largest storage facilities – with a capacity of 300 MW/450 MWh – in Victoria, Australia.13 Around 150 firefighters and 30 vehicles were deployed to fight the fire. The fire started in a 13‑tonne module with a capacity of 3 MWh, which was housed in a container about 15 meters long, and then spread to an adjacent container. The fire took three days to extinguish as the firefighters’ tactics were limited to cooling the outside of the containers to prevent the fire from spreading. Fortunately, there were no injuries or fatalities.

- In California in September 2021, damage occurred at what is currently the world’s largest battery storage facility when several lithium‑ion battery modules overheated.14 Existing safety measures (including targeted cooling systems, sprinklers and the precautionary presence of the local fire brigade) prevented the worst from occurring. The plant was shut down to investigate the cause of the overheating, repair the affected modules repaired and put it back into operation as quickly as possible.

Finally, although not a large-scale battery storage facility, another loss worth noting occurred in a storage building in the U.S. in July 2021.15 More than 200,000 lithium‑ion batteries (ranging from cell phone batteries to car battery packs) ignited, resulting in multiple explosions. Due to the enormous amounts of smoke and clouds of pollutants, more than 1,000 people had to be evacuated before the fire brigade brought the fire under control using tons of dry Portland cement.16

Loss causes

The triggers for such events are many and varied, ranging from production errors during cell manufacture to external influences. The investigation of the South Korean fires (2017–2019) revealed four typical causes:17

- Inadequate protection and control systems (e.g. against over‑voltage)

- Poor management of the operating environment

- Faulty installation

Looking more widely, root causes of damage often involve:

- Thermal events such as temperature increase due to failure of the air conditioning/ventilation system or incorrect design parameters

- Electrical events, e.g. a short circuit due to a defect in the battery cell or overvoltage charge

- Mechanical events, such as failure due to damage to a cell during the manufacturing or installation process or operation.

Exothermic reactions can lead to a thermal runaway – a chain reaction that leads to a decomposition reaction producing massive heat and gas development in the cell – which spreads quickly to neighboring cells.18 Once this process has begun, it is difficult to stop. Large amounts of heat as well as flammable and toxic gases – such as carbon monoxide (CO), hydrogen chloride (HCl), hydrogen fluoride fluoride (HF), and also heavy metal compounds – are released. This formation of flammable gases can create an explosive atmosphere inside a battery room or container.

Fires triggered by exothermic reactions proceed quickly, intensely and with massive smoke development due to the cell materials used. In the case of thermal runaway, rapid extinguishing is not possible; the only option is to stop the process by continuous cooling. The energy released in such a fire can be up to ten times the electrochemically stored energy of lithium‑ion cells. Since this is a chemical reaction of cell components, it should be noted that after the cooling measures have been stopped, a new ignition can occur at any time – even hours or days – after the fire has supposedly been extinguished. This can only be counteracted by intensive and permanent cooling of the affected cells or quarantine storage of the damaged cells until all electrical energy has been discharged. Attempts to limit the effects of fire with extinguishing systems (e.g. spraying or sprinkler systems), have been successful but can only cool the source of the fire, not extinguish it. In the case of cars, a burning e‑vehicle is sometimes immersed in a container filled with water.

Fire protection

As fighting lithium‑ion battery fires can be very difficult, it’s all the more important to take measures to prevent such events happening in the first place, or to limit them when they do. Accordingly, guidelines and standards are being developed worldwide detailing the planning, construction and running of large battery storage facilities.19

Planning and construction measures

Whether the facility is located in a building or outdoors is a crucial factor. As previous losses have shown, fire brigades have a significantly better chance of fighting fires in open areas, simply because of the accessibility.

Another hugely important aspect is the separation of individual large-scale storage modules/containers so that, in the event of a fire, the fire is prevented from spreading to neighbouring modules/containers. For systems set up outdoors, the distance should be at least 20 metres. This enables the fire brigade to set up so‑called barricade positions around the container concerned.

For facilities located inside, the bulk storage area should preferably be located at the outer edge of the site and be easily accessible from outside. It should also be separated from the rest of the building by fire walls, or at the very least constructed as a fire-resistant partitioned space. Such a space should be divided into several smaller sections by further fire-resistant walls to reduce the ability for a fire to spread. It’s also recommended that other important equipment (i.e., transformers, inverters and substations), be spatially or structurally separated from the actual battery modules/equipment.

The overall fire load of a large-scale storage facilities should be kept as low as possible; if the facility is housed inside, a solid fire-resistant construction made of non‑combustible components is preferable. In addition, non‑combustible materials should be used for the insulation of the battery containers and the choice of ventilation and extinguishing systems should be considered carefully.

Since the risk of an explosion during a fire cannot be ruled out, it’s advisable to provide appropriate pressure relief openings in the containers or buildings to release the resulting pressure into the environment without further danger.

Technical measures

To have a chance to bring a battery fire under control, fire brigades need to be able to intervene as swiftly as possible, ideally while the fire is still in its early stages. The following measures are recommended:

- Installation of technology that can detect aspirating smoke, trigger an extinguishing system, and communicate with the fire station detector technology

Initial findings suggest that standard fire alarm systems are suboptimal for detecting fires in large-scale storage modules. This is because permanent air conditioning is required to maintain the operating temperature, leading to a strong dilution of released smoke and gases, which can delay the alarm being triggered. Given heat/fire development is so rapid, aspirating smoke detector technology is instead recommended. As a minimum requirement, the alarm should be connected to an office manned around the clock and preferably linked directly to the responding fire brigade’s control centre. When a fire is detected, an automatic extinguishing system should also be triggered, if available, and the battery system should be automatically disconnected from the power supply. - Additional monitoring systems

To detect any threat of a thermal runaway promptly (and limit the fire spreading to other modules), additional monitoring measures should be employed. These include: thermal imaging cameras, gas detectors (such as carbon monoxide and hydrogen detectors), temperature sensors, and air quality monitoring sensors. For example, in the event of an internal battery failure, highly flammable electrolyte gases as well as small amounts of pyrolysis gases are released as the plastic battery casing heats up, indicating the onset of thermal runaway. It’s expected that detection technology will continue to improve over time to detect critical developments within cells and modules earlier. - Extinguishing systems

Equipping individual battery rooms with automatic water extinguishing systems (e.g. sprinklers and water spray extinguishing systems) has proved effective, since they cool the battery packs and slow or stop the reaction taking place. It should be noted that if the cooling measures are discontinued (e.g. due to a lack of water), the reaction may accelerate again and lead to renewed ignition. Other extinguishing systems (e.g. aerosols or gaseous extinguishing systems), are often used in battery system enclosures to suppress electrical fires that could spread to adjacent battery modules. However, they are not suitable for extinguishing battery fires or preventing thermal runaway from occurring. - Temperature control systems

Battery plant rooms or container modules should have adequate ventilation or air conditioning to ensure a constant room and operating temperature (in line with the manufacturer’s specifications). This is essential as the service life of batteries is highly dependent on maintaining a constant operating and room temperature. Therefore, if cooling and ventilation systems fail, an alarm should be activated. In the event of a fire, the operation of the ventilation systems should be maintained as far as possible to remove flammable and toxic gases, unless there is a risk of significant environmental damage. - Correct planning and installation

Care must also be taken to ensure that other components of the system, such as cable systems, air conditioning, control cabinets and inverters, are installed outside of the battery system rooms/containers, so that any fires that occurs there cannot spread to the battery systems. - Lightning and surge protection systems

The entire installation should have a lightning and surge protection system.

Organizational measures

Some of the causes of large-scale storage fires in South Korea have been attributed to poor construction and lack of experience on the part of the design and installation companies. Therefore, companies must be selected carefully, and inspections should be carried out regularly during the construction phase. Once a plant is in operation, monthly checks and thermographic inspections should be conducted with the help of a defined maintenance plan. Any deficiencies found should be rectified immediately. When drawing up a maintenance plan, the manufacturer’s specifications provide good information on the inspection, testing and maintenance of the large-scale storage system and its components. For example, this includes measuring the internal resistance of the cells, checking for leaking liquids, force-locking of the connections and checking cables and lines for damage.

Other measures include the designation of rescue and escape routes (which are also possible attack routes for the fire brigade), equipment and marking of fire-fighting equipment, marking of the hydrant system, training of operating and maintenance personnel on the particular hazards, and other fire protection measures deemed appropriate for commercial operations. These include, but are not limited to, a fire plan, an alarm plan, and a disaster management and business continuity plan.

Defensive measures

To create optimum conditions for rapid and efficient firefighting, an appropriate fire brigade bypass should be provided which allows the fire brigade to initiate rapid countermeasures safely. Hydrants and other means of drawing water for fire-fighting purposes should be marked accordingly and kept ready for use.

When planning for a large-scale battery storage facility, it is also good practice to involve the local fire brigades and response teams from the start and to understand their concerns and jointly develop emergency strategies and response plans. For the duration of a large-scale storage facility’s life, the fire brigade should be familiarised on a regular basis with the site and its characteristics, and an appropriate fire drill should be held once a year.

As claims in the U.S., South Korea and the UK have shown, tackling battery storage fires can threaten the “life and limb” of firefighters. As knowledge about optimal firefighting is still evolving, it can be difficult for fire brigades to assess the risks. Discussing the specific conditions and characteristics of the plant in advance can be advantageous. The main topics should include cooling/extinguishing measures, handling of damaged batteries, occurrence of toxic and flammable gases and existing shutdown devices in the plant.

In the event of a fire, it is to be expected that large quantities of contaminated extinguishing water will be produced, and as a result of the necessary prolonged cooling of affected battery storage tanks, the site should have appropriate extinguishing water collection facilities to prevent uncontrolled run‑off into the surrounding area.

Further measures

After an event, battery storage systems should not be put back into operation, even if no direct damage is detected. The entire affected container pack should be replaced, as contamination and water in the batteries and inverters can cause further short circuits and possibly self‑ignition.

Checklist for underwriters

Though not an exhaustive list, the following are important points for underwriters tasked with assessing the exposure of large battery storage facilities to consider:

- Latest survey report

- Address, location and whether the site is indoors or outdoors

- Neighbourhood hazards (e.g. pipelines, chemical plants, tank farms)

- Type, use and year of construction of the plant

- Potential exposure to natural hazards (bushfires, earthquakes, floods, storms, landslides, subsidence, etc.)

- Possible political dangers, including SRCC (Strike, Riot, Civil Commotion), terrorism, other attacks

- Existing insurances (e.g. machine breakage, electronics insurance)

- Type of insurance desired, underlying wording and scope of coverage (e.g. named perils, all risks coverage, machinery breakdown)

- Insured values and basis of valuation and indemnification

- Agreed initial risk amounts and liability limits

- Agreed deductibles

- Underinsurance scheme

- Agreed extensions of cover, additional conditions and exclusion clauses (e.g. cyber, war, terrorism, machinery breakdown)

- Existing safeguards:

- Distances between the individual battery containers and from neighbouring plants and buildings

- Existing fire walls

- Use of fire compartments (or at least fire-resistant compartments)

- Fire detection and other alarm systems, including alarm forwarding and automatic shutdown of electrical equipment/systems that may be provided

- Existing fire extinguishing systems

- Existing cooling and ventilation equipment, equipping of the containers/rooms with pressure relief as well as flue gas and heat dissipation systems

- Existing extinguishing water supply, quantities and collection facilities

- Responsible fire brigade (e.g. type of fire brigade, local knowledge, exercise use)

- Accessibility, attack and installation areas for the fire brigade, plus design features of the containers/building type with details of the materials used, details of maintenance and servicing plans

- Consequences of damage in the event of failure of parts or the entire large-scale storage facility

- Claims history

- MFL/ PML surveyor’s estimate

Conclusion

As loss experiences repeatedly show, fighting fires in large-battery storage facilities presents specific challenges. Burning battery cells cannot simply be extinguished using traditional approaches but require complex and protracted fire-fighting operations. Preventive fire protection measures can only avert damage to a limited extent, especially if thermal runaway occurs and the consequences of damage from a Property insurance perspective are considerable.

Carefully determining and evaluating the exposure during the underwriting process is therefore vital to drawing appropriate conclusions for premium calculation and underwriting capacity.